Have you heard of the terms HMR (High Moisture Resistance) and plywood when looking for materials for furniture or interior projects? Both are popular and often used, but many people are still confused about which one is the most suitable. Moreover, each material has its own characteristics, advantages, and disadvantages that can affect the final result and durability.

So, to help you make the right choice and avoid regret later on, let’s take a relaxed but comprehensive look at the comparison between HMR and plywood. We’ll cover everything from strength and water resistance to price. Be sure to read on so you can decide which material best suits your needs.

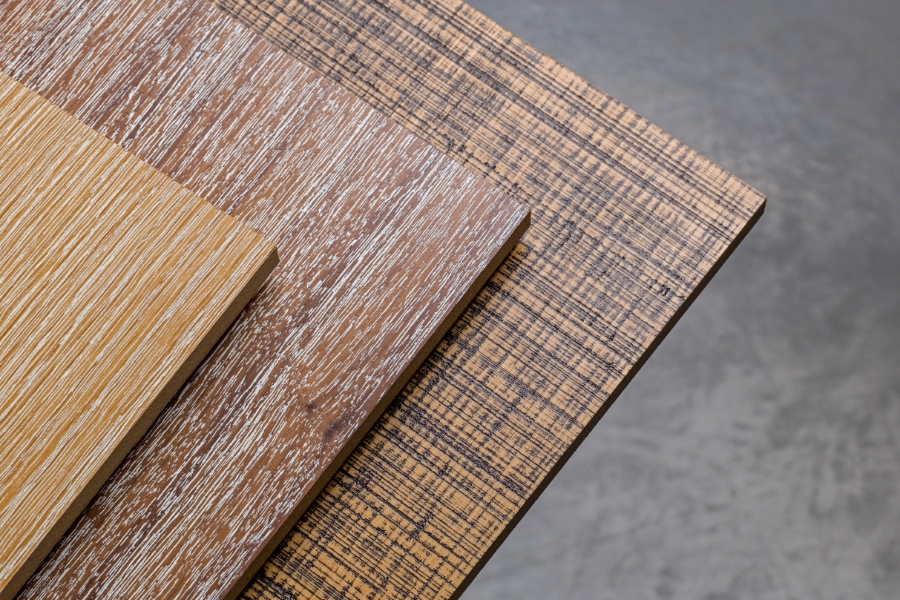

HMR VS Plywood Comparison

Before making a decision, it is very important for you to know the basic comparison between HMR and plywood. By understanding the characteristics of each, you can choose the right material for your needs and budget. Let’s take a look at each one!

1. Material Composition

HMR is plywood coated with a special resin to increase its resistance to moisture. This material is made from wood powder that is glued together and then compacted to form a strong, dense board. Meanwhile, plywood consists of several layers of wood veneer glued together with the grain running in opposite directions. This structure makes plywood more sturdy and stable.

2. Moisture Resistance

The main advantage of HMR is its ability to withstand moisture. This material is designed for use in wet or humid areas such as kitchens and bathrooms, without easily expanding or deteriorating. Plywood also has fairly good resistance, but not as much as HMR. Without a protective coating, plywood can absorb water and deteriorate over time.

3. Strength and Durability

HMR is strong enough for various furniture needs, but plywood is generally superior in terms of structural strength. The cross-laminated layers of plywood make it more resistant to heavy loads and pressure. If a project requires a sturdy material to support heavy loads, plywood may be the best choice. Conversely, for light to medium needs, HMR can be a more efficient option.

4. Manufacturing Process and Cost

The manufacturing process for HMR is relatively simpler than plywood, which requires wood veneer processing. This makes HMR more affordable, suitable for projects with limited budgets. Plywood is usually more expensive, but offers advantages in terms of strength.

5. Applications and Uses

HMR is typically used for furniture, cabinets, and interior applications that require moisture resistance. Plywood is more commonly used for construction, such as floors, walls, ceilings, and furniture that requires extra strength.

So, now you know the comparison between HMR and plywood from various perspectives. The bottom line is to choose the material that best suits your needs and project conditions. If you need extra moisture resistance, HMR could be the solution. However, if strength and long-term durability are what you’re looking for, plywood is worth considering. That way, the end result will not only be neat and durable, but also leave you satisfied without any regrets later on.

For HMR, plywood, or other high-quality wood products, you can check out Hojaya. As a trusted wood distributor, we offer a wide range of materials, including plywood, blockboard, MDF, and particle board, all with guaranteed quality and competitive prices.

Don’t wait until your project is delayed due to choosing the wrong material—start now by selecting high-quality wood from Hojaya!